Particleboard is a wood-based panel manufactured under pressure and heat from particles of wood (flakes, chips, shavings, sawdust and similar) and/or other lignocellulosic material in particle form (flax shives, hemp shives, bagasse fragments and similar) with the addition of an adhesive.

How is it made?

Wood chips comprise the bulk of particleboard and are prepared in a mechanical chipper generally from coniferous softwoods, principally spruce, although pine and fir and hardwoods, such as birch, are sometimes used. Particleboards may also incorporate a large proportion from recycled sources. These chips are generally bound together with synthetic resin systems. The chips are formed into a mat and are then pressed between heated platens to compress and cure the panel. The finished panels are then sanded and cut to size.

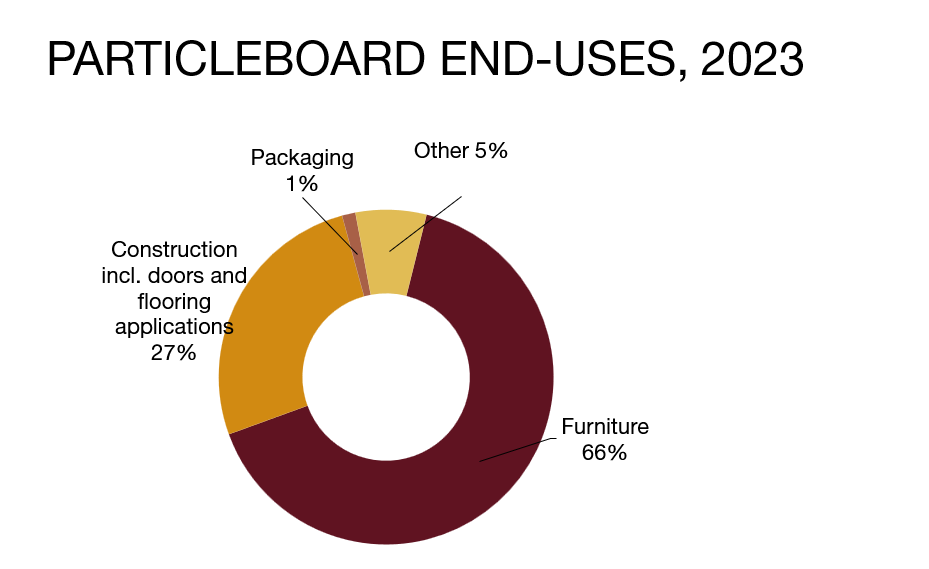

What is it used for?

Large quantities of particleboard are used in the manufacture of kitchen units and worktops, as well as in dining-room and bedroom units; these generally have a veneered or laminated finish. In construction applications its good mechanical performance, which is the same along and across the panel, renders it appropriate for use as floor decking, and in doors. Packaging is another common application for particleboard, or chipboard as it is often known.

Properties

Moisture resistance, high mechanical performance, fire retardance and acoustic insulation are all properties which can be achieved by using specific types of particleboard.

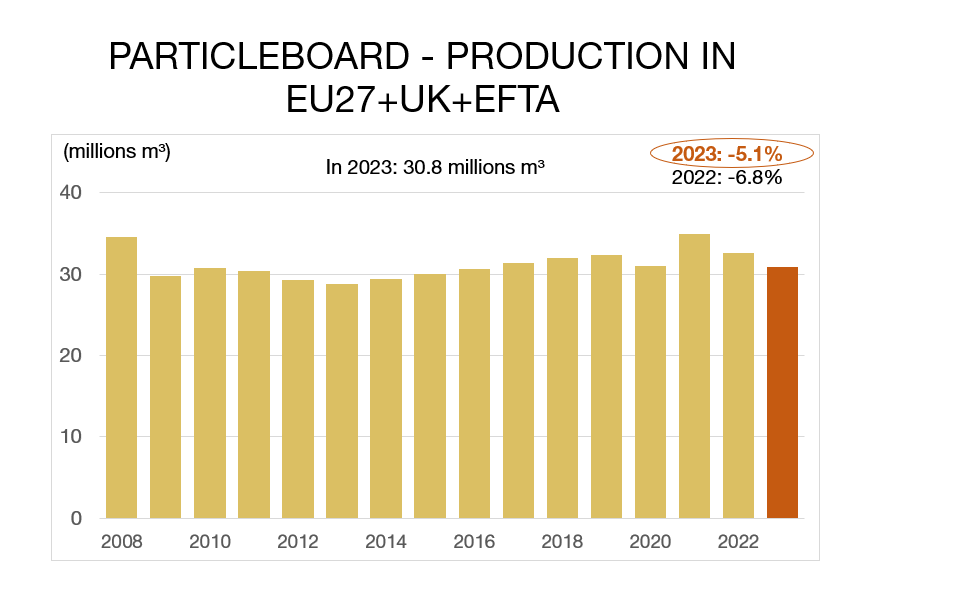

Economic Impact