OSB is an engineered wood-based panel material in which long strands of wood are bonded together with a synthetic resin adhesive. OSB is usually composed of three layers, with the strands of the outer two layers orientated in a particular direction, more often than not in the long direction of the panel.

How is it made?

The timbers used in OSB manufacture include both softwoods (spruce, pine) and hardwood (aspen). Wood strands are cut tangentially from debarked logs which are held longitudinally against rotating knives. After drying, these flakes are generally sprayed with a synthetic resin binder and wax and then bonded under heat and pressure between steel belts.

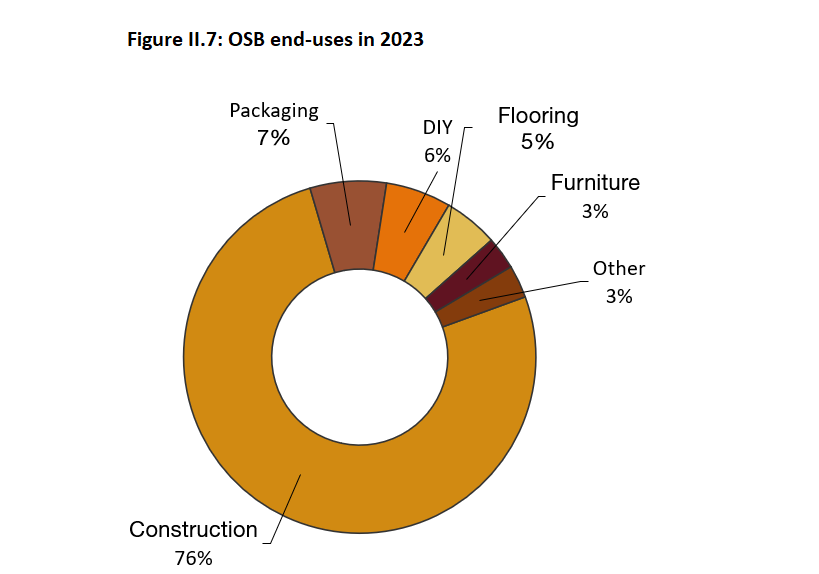

What is this used for?

Because of its lay-up and composition, OSB is primarily a panel for construction and is widely used for flooring, flat roof decking and wall sheathing.

Properties

OSB’s strength mainly comes from its uninterrupted wood fibre, interweaving of long strands and the degree of strand orientation in the surface layers. Waterproof and boil proof resin binders are combined with the strands to improve internal strength, rigidity and moisture resistance.

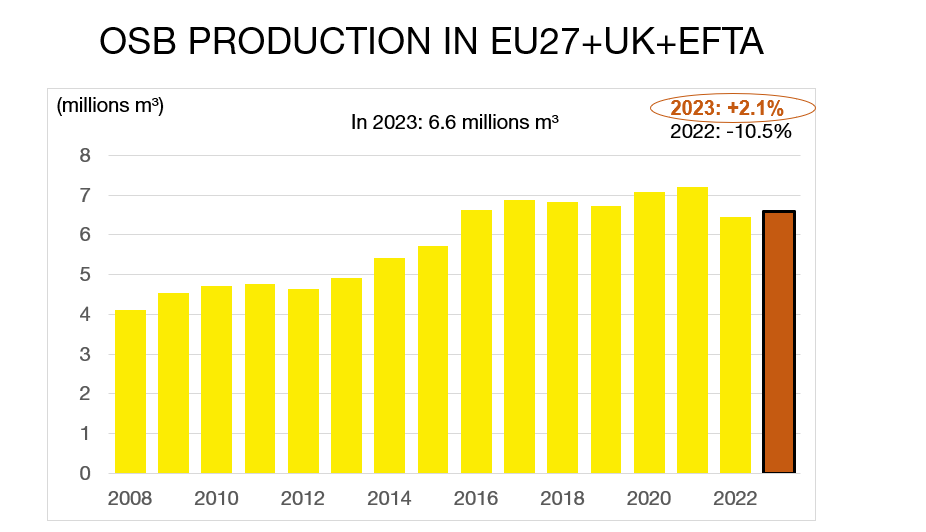

Economic impact

More about OSB

Description

OSB (Oriented Strand Board) is an engineered wood-based panel consisting of strands of wood which are bonded together with a synthetic resin; the strands are pressed together in layers. In the outer layers strands are generally oriented longitudinally in line with the panel length, whereas in the middle layers strands generally lie in a cross wise direction.

Composition

The wood species used in OSB manufacture include both softwoods (spruce, pine) and some hardwood. Wood strands are cut tangentially from debarked logs which are held longitudinally against rotating knives. The ribbon of strands produced is usually about 75 mm wide and this breaks up on handling to produce individual strands which are typically 100 mm along the grain and from 5 to 50 mm across the grain.

After drying, these strands are sprayed with a synthetic resin binder. The resin types typically used include Phenol formaldehyde (PF), melamine fortified Urea Formaldehyde (MUF) or isocyanate (PMDI), all of which are moisture resistant binders. In Europe, it is common to use a combination of binders, typically PMDI would be used in the core and MUF in the face layers and this has the advantage of reducing press cycles whilst imparting a bright appearance to the surface of the panel.

Appearance

OSB is readily identified by its relatively large and long wood strands. The orientation of the surface strands is not always visually apparent, especially in small cut pieces of panel. The main merits of OSB lie in the field of its mechanical performance, which is directly related to the geometry of the strands and their orientation within the panel. Although OSB is made up of relatively large strands of wood, its surface is relatively smooth and this can be further enhanced by sanding without loosing the aesthetic character which is unique to OSB.

OSB varies in colour from a light straw colour to a medium brown depending on wood species used, resin system adopted and pressing conditions employed. It contains no knotholes, core voids or points of weakness.

Density, mass and sheet size

Panel density (and thus panel mass) varies depending upon the product, being affected by the timber species and the manufacturing process. Typical densities are 600-680kg/m_. Thus, for example, a 2400 x 1200 x 12mm panel will weigh approximately 20 kg.

Panel sizes commonly available are 2440mm x 1200mm, 2440mm x 1220mm and 2500mm x 1250mm in thicknesses of 6mm to 40mm.

Other sizes are available or can be produced to order. Panels are produced with either square or tongued & grooved (T&G) edges.

Applications

Due to its high mechanical properties and the orientation of the strands within panels, OSB is particularly suitable for load-bearing applications in construction and is widely used for flooring, roof decking and wall sheathing, but there is also a wide field of other applications where OSB as a wood-based panel product can be utilised. Different grades of the product are available for different levels of loading and different environmental conditions. Guidance on the use of OSB in these load-bearing applications is given in ENV 12872 and EN 13986. OSB is a quality, precision-engineered product that can satisfy the same applications and loading conditions as plywood and in some cases a thinner OSB panel may be used thereby reducing costs.

Large quantities of OSB are also used for sarking and industrial packaging and in site hoardings and pallet tops.

Specification

It will soon be a legal requirement to demonstrate that OSB used in construction satisfies the requirements of the European Construction Products Directive. This legal requirement is written into national building regulations. Manufacturers shall demonstrate compliance with the legal requirements by showing that their OSB complies with the harmonised standard EN 13986 “Wood-based panels for use in construction – Characteristics, evaluation of conformity and marking”. This standard should be published before the end of 2001. It calls up EN 300 “Oriented Strand Boards (OSB) – Definitions, classification and specifications”, which will have to be used when specifying OSB.

Four grades of OSB are defined in EN 300 in terms of their mechanical performance and relative resistance to moisture. These are:

OSB/1 – General purpose boards and boards for interior fitments (including furniture) for use in dry conditions.

OSB/2 – Load-bearing boards for use in dry conditions.

OSB/3 – Load-bearing boards for use in humid conditions

OSB/4 – Heavy-duty load-bearing boards for use in humid conditions.

Mechanical properties

The threshold value requirements for specified mechanical properties of the 4 OSB grades in EN 300 can be summarised as indicated in the following tables. The values are 95 percentiles (5 percentile values in the case of swelling in thickness) and are characterised by a moisture content in the material corresponding to a relative humidity of 65% and a temperature of 20°C. This implies that these specified mechanical properties have to be controlled according to statistical principles and that 95% of the test values on individual samples have to exceed (or remain below in the case of swelling in thickness) the respective threshold value requirement in EN 300.

Threshold value requirements for OSB/1Â

Requirement |

|||||

Test |

Unit |

Thickness range (mm, nominal)

|

|||

|

Property

|

method

|

6 to 10

|

> 10 and < 18

|

18 to 25

|

|

| Bending strength – major axis | EN 310 |

N/mm3

|

20

|

18

|

16

|

| Bending strength – minor axis | EN 310 |

N/mm3

|

10

|

9

|

8

|

| Modulus of elasticity in bending – major axis | EN 310 |

N/mm3

|

2500

|

2500 |

2500

|

| Modulus of elasticity in bending – minor axis | EN 310 |

N/mm3

|

1200

|

1200

|

1200

|

|

Internal bond |

EN 319 |

N/mm3

|

0.30

|

0.28

|

0.26

|

|

Swelling in thickness – 24 h |

EN 317 |

%

|

25 |

25

|

25

|

Threshold value requirements for OSB/2

Threshold value requirements for OSB/3

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Requirement |

|||||

Test |

Unit

|

Thickness range (mm, nominal) |

|||

|

Property

|

method

|

6 to 10

|

> 10 and < 18

|

18 to 25

|

|

| Bending strength – major axis |

EN 310

|

N/mm3

|

22

|

20

|

18

|

| Bending strength – minor axis |

EN 310

|

N/mm3

|

11

|

10

|

9

|

| Modulus of elasticity in bending – major axis |

EN 310

|

N/mm3

|

3500

|

3500

|

3500

|

| Modulus of elasticity in bending – minor axis |

EN 310

|

N/mm3

|

1400

|

1400

|

1400

|

| Internal bond |

EN 319

|

N/mm3

|

0.34

|

0.32

|

0.30

|

| Swelling in thickness in 24h |

EN 317

|

%

|

15

|

15

|

15

|

Requirements for moisture resistance |

|||||

| Bending strength after cyclic test – major axis |

EN 321

+

EN 310

|

N/mm3

|

9

|

8

|

7

|

|

OPTION 1 Internal bond after cyclic test |

EN 321

+

EN 319

|

N/mm3

|

0.18

|

0.15

|

0.13

|

|

OPTION 2 Internal bond after boil test |

EN 1087-1

+

EN 319

|

N/mm3

|

0.15

|

0.13

|

0.12

|

Threshold value requirements for OSB/4

Requirement |

|||||

Test |

Unit

|

Thickness range (mm, nominal) |

|||

|

Property

|

method

|

6 to 10

|

> 10 and < 18

|

18 to 25

|

|

|

Bending strength – major axis

|

EN 310

|

N/mm3

|

30

|

28

|

26

|

|

Bending strength – minor axis

|

EN 310

|

N/mm3

|

16

|

15

|

14

|

|

Modulus of elasticity in bending – major axis

|

EN 310

|

N/mm3

|

4800

|

4800

|

4800

|

|

Modulus of elasticity in bending – minor axis

|

EN 310

|

N/mm3

|

1900

|

1900

|

1900

|

|

Internal bond

|

EN 319

|

N/mm3

|

0.50

|

0.45

|

0.40

|

| Swelling in thickness – 24 h |

EN 317

|

%

|

12

|

12

|

12

|

Requirements for moisture resistance |

|||||

| Bending strength after cyclic test – major axis |

EN 321 + EN 310

|

N/mm3

|

15

|

14

|

13

|

|

OPTION 1 Internal bond after cyclic test |

EN 321 + EN 319

|

N/mm3

|

0.21

|

0.17

|

0.15

|

|

OPTION 2 Internal bond after boil test |

EN 1087-1

+Â EN 319Â |

N/mm3

|

0.17

|

0.15

|

0.13

|

Physical properties

a) Climate

Like other wood-based panel products, OSB is hygroscopic and its dimensions change in response to a change in humidity. A 1% change in moisture content increases or decreases the length, width and thickness of the different grades of OSB by the amounts set out in the table below.

Type of panel |

Specification |

Dimensional change at 1% change in panel moisture content |

||

|

Length %

|

Width %

|

Thickness %

|

||

|

OSB

|

EN 300, OSB/2

|

0.03

|

0.04

|

0.7

|

|

EN 300, OSB/3

|

0.02

|

0.03

|

0.5

|

|

|

EN 300, OSB/4

|

0.02

|

0.03

|

0.5

|

|

Relative humidityat 20° C |

Approximate equilibrium moisture content |

|

30%

|

5%

|

|

65%

|

10%

|

|

85%

|

15%

|

OSB must be conditioned to bring it into equilibrium with its environment before it is fixed. This is usually achieved by loose stacking of the panels in the room where they will be used prior to fixing them. The time required for the panels to achieve equilibrium moisture content will vary depending upon the temperature and relative humidity in the building. The likely equilibrium moisture content levels of OSB in various conditions are as follows:

In a building with intermittent central heating: 8-10%

In an unheated building: up to 15%

b) Biological attack

Typically OSB will not be attacked by wood-boring insects common in temperate climates. It can be used in hazard classes 1, 2 and 3 as defined in EN 335-1 “Durability of wood and wood-based products — Part 1: Definition of hazard classes of biological attack”. For these three hazard classes, the respective moisture content of OSB and the organisms that may attack OSB under the specified conditions are given in EN 335-3 “Durability of wood and wood-based products — Part 3: Application to wood-based panels”.

c) Water vapour permeability

d) Thermal conductivity

The thermal conductivity (l ) of OSB is 0.13 W/m.K for a mean density of 650 kg/m_.

e) Reaction to Fire

Storage and handling

Careful storage and handling is important to maintain panels in their correct condition for use; thus, OSB must be protected from rain and accidental soaking. During transport, it is particularly important to keep edges well covered. Panels should be stored flat in an enclosed, dry building. When handling boards, the edges and corners should be protected against damage.

Working with OSB

a) Mechanical joints and fixings

b) Adhesive-bonded joints

The joint parts should be accurately machined.

- Use sharp cutters to avoid tearing or burnishing the surfaces to be bonded.

- Use a high solids content adhesive with low flowing properties such as polyvinyl acetate or urea formaldehyde.

- Locate mating pieces accurately and hold them under pressure while the adhesive sets.

- The width of grooves machined in OSB should be limited to about one-third of the thickness of the board. The depth of groove is typically about one-half of the board thickness.

- Allow adhesive-bonded joints to condition for several days before sanding and finishing; this avoids the appearance of sunken joints and is essential with high-gloss finishes.

- A tongue and groove joint is very efficient, provided the fit of the joints is not too tight to cause a split along the edge.

- When attaching lippings, the tongue should be machined on the solid wood piece

c) Finishing

Where smooth surfaces are required pre-sanded panels should be specified.

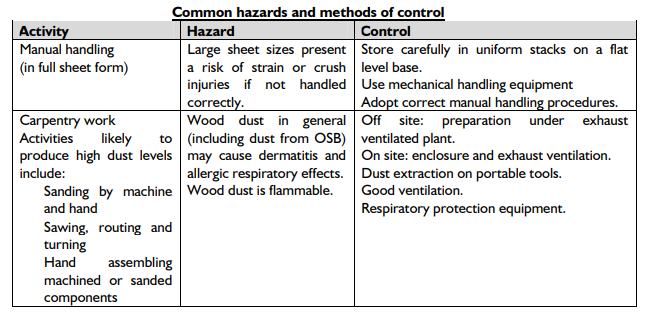

Health and Safety

a) Dust

OSB will generate dust when it is machined and this dust, like any other wood dust, is a potentially hazardous substance and must be controlled. There is no evidence that exposure produces health effects that are different in nature to those associated with exposure to similar levels of dust from other wood sources.

Dust from cutting operations can be controlled adequately by complying with the Occupational

b) Formaldehyde

Studies indicate that anyone machining OSB in mechanically ventilated situations is exposed to extremely low levels of free formaldehyde.

– Class E2 > 8 to £ 30mg/100g