Hardboards are formed with wood fibre and made by high pressure compression and temperature during a pressing process.

How is it made?

Wet process fibreboards are made by reducing steamed wood into fibres and by using the natural lignins as a binder during the pressing process. Depending on the degree of pressing involved, and hence the final density of the panel, the product is termed softboard or hardboard.

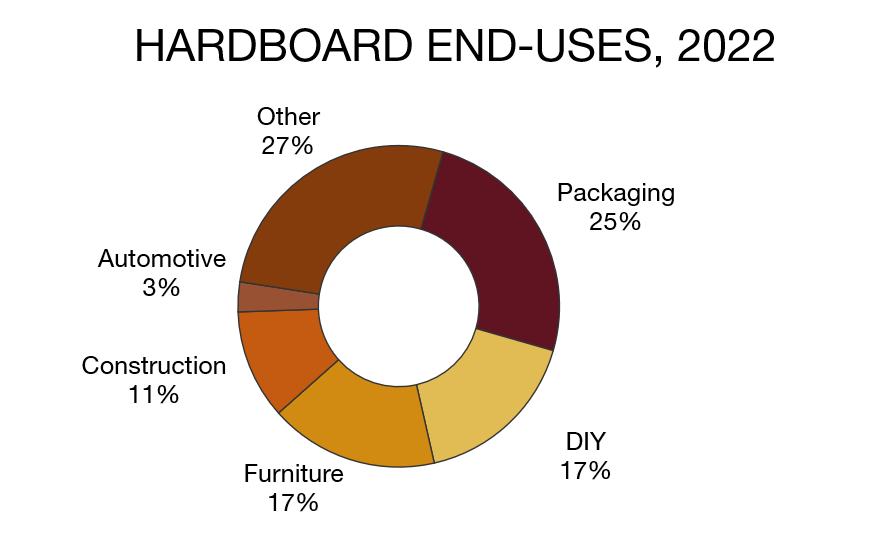

What is this used for?

Raw and lacquered hardboard panels are used in many applications including construction, packaging, furniture, upholstery, toys, and automobile and caravan interiours.

Hardboard is often required for packaging of fruits, vegetables and mineral water bottles because it is a natural product.

Properties

The high density boards satisfy the most demanding applications as a result of tempering or other treatments that achieve great physical and mechanical characteristics and excellent dimensional stability. Producers can offer customers additional special services including cut to size, and drilling and milling.

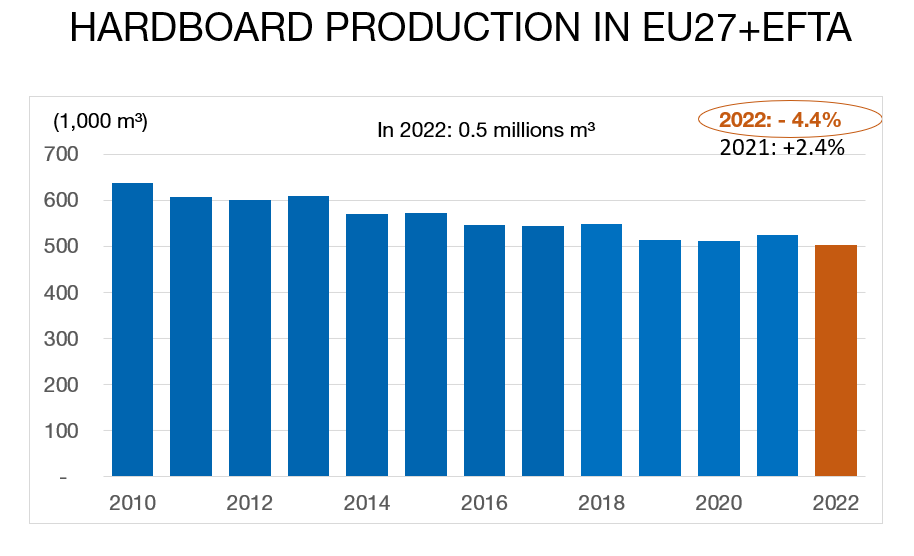

Economic impact

More about Natural Fibre Board